Large Warehouse Tent

In the dynamic landscape of modern logistics, manufacturing, and event management, the need for flexible, cost-effective, and rapid storage solutions has never been more pronounced. Large warehouse tents, as a practical alternative to traditional brick-and-mortar warehouses, have emerged as a game-changer in addressing these evolving needs. Unlike permanent structures that require extensive construction time, substantial capital investment, and rigid design, large warehouse tents offer unparalleled adaptability, allowing businesses to expand or modify their storage space according to fluctuating demands.

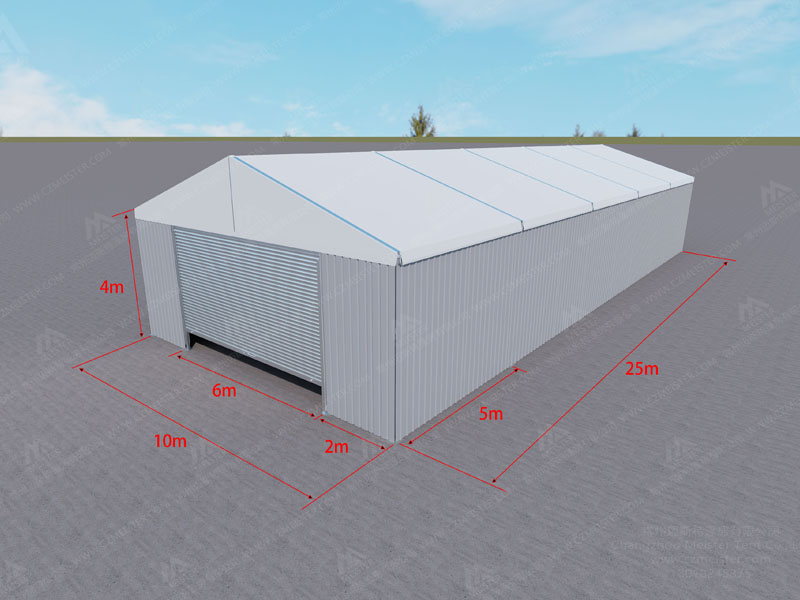

To understand the appeal of large warehouse tents, it is first essential to examine their structural design and engineering principles. Unlike conventional warehouses that rely on load-bearing walls and fixed foundations, large warehouse tents are typically constructed using a modular frame system combined with a high-strength fabric cover. The frame, often made of galvanized steel or aluminum alloy, is designed to be lightweight yet robust, capable of withstanding various environmental pressures such as wind, snow, and heavy rainfall. The modular nature of the frame allows for easy assembly and disassembly, as well as flexible expansion by adding additional sections. This modular design means that large warehouse tents can be customized to a wide range of sizes, from small storage units of a few hundred square meters to massive facilities spanning several thousand square meters. The fabric cover, which serves as the primary barrier against the elements, is usually made of PVC-coated polyester or polyethylene, materials known for their durability, water resistance, and UV protection. The combination of a sturdy frame and a reliable fabric cover ensures that large warehouse tents can provide a safe and stable storage environment for a variety of goods, from raw materials and finished products to equipment and machinery.

One of the most significant advantages of large warehouse tents is their cost-effectiveness compared to permanent warehouses. Constructing a traditional warehouse involves substantial expenses, including land acquisition, foundation construction, material costs, labor costs, and regulatory fees. In contrast, large warehouse tents eliminate many of these costs. They require minimal site preparation, often needing only a flat and level surface, which significantly reduces construction time and expenses. The materials used in large warehouse tents are also generally more affordable than those required for permanent structures, and the modular design reduces labor costs associated with assembly. Additionally, large warehouse tents are often considered temporary structures in many regions, which can lead to lower tax burdens and fewer regulatory hurdles. For businesses that need additional storage space on a short-term basis or are operating on a tight budget, large warehouse tents offer a cost-efficient solution that does not compromise on quality or functionality.

Flexibility and adaptability are other key strengths of large warehouse tents. In today's fast-paced business environment, market demands can change rapidly, requiring businesses to adjust their storage capacity quickly. Large warehouse tents can be installed in a matter of days or weeks, depending on the size, which is a fraction of the time required to build a permanent warehouse. This rapid deployment makes them ideal for emergency situations, such as natural disasters where temporary storage is needed for relief supplies, or for businesses experiencing sudden growth or seasonal peaks in demand. For example, agricultural businesses often use large warehouse tents to store crops during harvest season, while retailers may use them to store additional inventory during holiday shopping periods. Furthermore, large warehouse tents can be easily relocated if needed. If a business moves its operations to a new location or no longer requires the additional storage space, the tent can be disassembled and transported to another site, making it a reusable asset. This flexibility allows businesses to respond quickly to changing market conditions and optimize their storage resources.

The diverse range of applications for large warehouse tents is a testament to their versatility. Beyond traditional storage, these tents are widely used in various industries and scenarios. In the logistics and transportation sector, large warehouse tents serve as temporary distribution centers, sorting facilities, and loading docks, helping to streamline operations during peak periods. In manufacturing, they are used as temporary production facilities, workshops, or storage areas for raw materials and finished products, allowing manufacturers to expand their production capacity without investing in permanent structures. The construction industry also benefits from large warehouse tents, using them as on-site storage for construction materials and equipment, as well as temporary offices and worker facilities. Additionally, large warehouse tents are popular in event management, serving as exhibition halls, conference venues, and temporary shelters for large-scale events such as concerts, festivals, and sports competitions. In the agricultural sector, they are used for crop storage, livestock housing, and greenhouse operations. Even in humanitarian and disaster relief efforts, large warehouse tents play a crucial role, providing temporary shelter for displaced persons and storage for food, water, and medical supplies. This wide range of applications highlights the adaptability of large warehouse tents to different environments and needs.

Material selection is a critical factor in determining the performance and durability of large warehouse tents. The frame material, as mentioned earlier, is typically galvanized steel or aluminum alloy. Galvanized steel is known for its high strength and corrosion resistance, making it suitable for use in harsh environments. Aluminum alloy, on the other hand, is lighter in weight, making it easier to transport and assemble, while still offering good strength and durability. The choice of frame material depends on the specific application and environmental conditions. The fabric cover is another important component, with PVC-coated polyester being the most common choice. PVC-coated polyester offers excellent water resistance, UV protection, and tear resistance, and it is also flame-retardant, which is crucial for ensuring the safety of stored goods. Polyethylene is another option, known for its lightweight and cost-effectiveness, although it may not be as durable as PVC-coated polyester in extreme conditions. Some high-performance fabric covers may also be treated with anti-mildew and anti-static coatings, making them suitable for storing sensitive goods such as electronics or food products. The quality of the materials used directly impacts the lifespan and performance of the large warehouse tent, so it is essential for businesses to choose materials that meet their specific requirements.

Proper maintenance is essential to ensure the longevity and performance of large warehouse tents. While these tents are designed to be durable, regular maintenance can help prevent damage and extend their lifespan. One of the key maintenance tasks is inspecting the frame and fabric cover regularly for signs of wear and tear, such as rust on the frame, tears or holes in the fabric, or loose connections. Any rust should be removed and the affected area painted to prevent further corrosion, while tears or holes in the fabric should be repaired promptly using patch kits designed for the specific material. It is also important to ensure that the frame connections are tight, as loose connections can compromise the structural integrity of the tent. In addition, the tent should be cleaned regularly to remove dirt, debris, and mold, which can damage the fabric over time. Cleaning can be done using mild soap and water, and the fabric should be allowed to dry completely before storing or reusing the tent. During extreme weather conditions, such as heavy snow or strong winds, it is important to take additional precautions, such as removing snow from the roof to prevent excessive weight and securing the tent with additional anchors if necessary. By following these maintenance guidelines, businesses can ensure that their large warehouse tents remain in good condition and continue to provide reliable storage space for years to come.

Looking to the future, the market for large warehouse tents is expected to grow steadily, driven by increasing demand for flexible and cost-effective storage solutions across various industries. Advances in material technology are likely to further improve the performance and durability of large warehouse tents. For example, the development of new high-strength, lightweight fabrics could make tents even more portable and durable, while improvements in frame materials could enhance their load-bearing capacity and corrosion resistance. Additionally, the integration of smart technologies into large warehouse tents is a potential trend. This could include the installation of sensors to monitor environmental conditions such as temperature, humidity, and air quality, as well as automated systems for ventilation and lighting. These smart features would make large warehouse tents more efficient and suitable for storing sensitive goods. Another trend is the growing focus on sustainability. Manufacturers are likely to develop more eco-friendly materials for large warehouse tents, such as recyclable fabrics and frames made from recycled materials. Additionally, the reusable nature of large warehouse tents aligns with the global push for sustainable development, as they reduce the need for new construction and minimize waste. As businesses continue to prioritize flexibility, cost-effectiveness, and sustainability, large warehouse tents are poised to play an even more important role in the global supply chain and various industries.

In conclusion, large warehouse tents have become a versatile and efficient storage solution that meets the evolving needs of modern businesses. Their structural design, cost-effectiveness, flexibility, and diverse applications make them an attractive alternative to traditional permanent warehouses. By selecting high-quality materials and following proper maintenance practices, businesses can ensure that their large warehouse tents provide reliable service for many years. With ongoing advances in technology and a growing focus on sustainability, the future of large warehouse tents looks promising, with even more innovative and efficient solutions expected to emerge. Whether used for temporary storage during peak seasons, emergency relief efforts, or as a permanent flexible storage solution, large warehouse tents have proven their value in a wide range of scenarios, making them an indispensable asset for businesses across the globe.