Industrial Warehouse Tent

Industrial warehouse tent as a new type of temporary or semi permanent storage facility, are widely used worldwide. This modular building structure is composed of high-strength aluminum alloy or steel frame and special tarpaulin, which can be quickly built and adapted to various industrial needs. Compared with traditional brick and concrete structure warehouses, industrial tents have significant advantages such as high cost-effectiveness, short construction period, and strong flexibility, making them particularly suitable for enterprises that require rapid expansion or temporary storage space.

The core advantages of industrial warehouse tents

Rapid deployment capability is one of the most prominent features of industrial tents. A standard sized industrial warehouse tent can be built and put into use within a few days, while traditional concrete warehouses typically require several months of construction time. This timeliness is particularly important for addressing seasonal storage needs, emergency warehouse expansion, or temporary project operations.

In terms of cost-effectiveness, industrial tents also perform excellently. Its construction cost is only 30% -50% of that of traditional warehouses, and it does not require complex foundation treatment or large-scale civil engineering. In addition, the modular design of the tent allows enterprises to flexibly adjust their scale according to actual needs, avoiding resource waste.

In terms of space utilization, modern industrial tents can provide column free large-span space (with a maximum span of up to 60 meters), and the internal space can be fully planned according to storage needs, without being limited by fixed structures. This design is particularly suitable for efficient storage and handling of large machinery, raw materials, or finished products.

Classification and application of industrial warehouse tents

classified by purpose

Raw material storage tent: used to store various industrial raw materials, usually equipped with ventilation systems and moisture-proof measures, suitable for the storage of wood, steel, chemical raw materials, etc. These types of tents often use fire-resistant tarpaulins and reinforced frames to ensure storage safety.

Temporary storage tent for finished products: providing solutions for seasonal products or temporarily increased inventory for enterprises. These types of tents are often equipped with temperature and humidity control systems to protect product quality from environmental impacts.

Equipment maintenance tent: provides temporary maintenance space for large industrial equipment, can be equipped with lifting equipment and dedicated ground protection layer. It is particularly common in environments such as mines and construction sites.

Classified by structural type

Standard arched tent: the most common form of industrial tent, with good wind resistance and drainage performance. The span is usually between 10-30 meters, suitable for most warehousing needs.

Multi arch connected tent: connected by multiple arch units to form a larger storage space, suitable for ultra large storage needs. This design can be infinitely extended, providing tens of thousands of square meters of continuous space.

Vertical Wall Tent: Adopting an upright wall design to maximize the use of internal space height, it is particularly suitable for scenarios that require high-rise shelving storage. Vertical walls also facilitate the installation of doors, windows, and ancillary equipment.

Technical parameters of industrial warehouse tents

Modern industrial warehouse tents have reached a considerable level of technical performance:

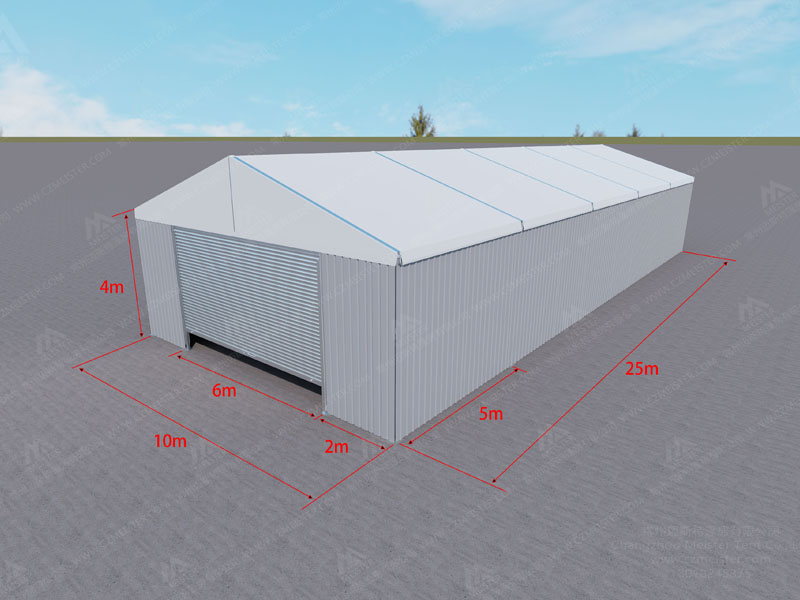

Span range: Standard product spans range from 6 meters to 60 meters, and larger spans can be customized according to demand

Length: Theoretically, it can extend infinitely, but in practical applications, it is commonly 20-100 meters

Height: Side height 2.5-8 meters, top height 4-15 meters

Wind resistance: up to 12 levels of wind (about 120km/h), specially designed to withstand stronger winds

Snow load: usually 0.3-1.5kN/m ², can be specially strengthened in high-altitude areas

Service life: High quality tents can last up to 15-20 years under normal usage conditions

Tent material

Framework materials

High strength aluminum alloy: 6082-T6 aviation grade aluminum alloy is the most commonly used tent frame material, with advantages such as light weight, high strength, and corrosion resistance. The surface has undergone anodizing treatment, further enhancing durability.

Hot dip galvanized steel structure: For tents with ultra large spans or heavy load requirements, hot-dip galvanized steel pipe frames are used, which have stronger load-bearing capacity. The thickness of the galvanized layer is usually not less than 80 μ m to ensure the anti-corrosion performance for long-term outdoor use.

cover material

PVC coated polyester fiber: a mainstream tent fabric with waterproof, flame-retardant, and UV resistant properties. The common thickness is 650-1000g/m ², and the service life can reach more than 10 years.

PVDF coated tarpaulin: Adding PVDF coating on the basis of PVC significantly improves weather resistance and self-cleaning, especially suitable for high corrosion environments such as chemical areas and coastal areas.

Fireproof tarpaulin: Complies with international fire safety standards and is used in flammable material storage areas.

Accessory parts

Modern industrial tents can be equipped with various functional accessories:

Ventilation system (side curtains, roof windows, mechanical ventilation devices)

Lighting system (LED mining lights, emergency lighting)

Temperature control equipment (insulation layer, heating system)

Safety facilities (smoke alarm, monitoring system)

Loading and unloading equipment (lifting platform, conveyor belt interface)

Installation and maintenance of industrial warehouse tents

Installation Process

Site preparation: Level the site and prepare the foundation. Concrete foundation, steel platform, or direct ground fixation can be selected

Frame assembly: Install main structures such as columns, arches, and beams in sequence

Laying of tarpaulin: Unfold and fix the tarpaulin on the frame, paying attention to even tension

Accessory installation: Install doors, windows, ventilation systems, and other functional accessories

Safety inspection: comprehensively check the stability of the structure and the reliability of each connecting part

Key points of daily maintenance

Regular cleaning: Use neutral cleaning agents to clean the surface of the tarpaulin to maintain good appearance and performance

Structural inspection: Monthly check if the frame connectors are loose and tighten them in a timely manner

Tent maintenance: repair minor damages to prevent expansion; Professional coating maintenance can be carried out every 2-3 years

Drainage system: Keep the drainage ditch unobstructed and avoid water accumulation

Winter maintenance: Timely remove snow from the top to prevent overloading

Industrial warehouse tents have become an indispensable infrastructure in modern logistics and industrial operations due to their flexibility, economy, and rapid deployment capabilities. With the advancement of technology and the expansion of application scenarios, this innovative warehousing solution will play a more important role in the industrial field, providing efficient and reliable responses to the space needs of enterprises.