Frame Warehouse Tent

In the realm of temporary and semi-permanent storage solutions, frame warehouse tents have emerged as a practical and flexible alternative to traditional brick-and-mortar warehouses. Designed to accommodate a wide range of storage needs across various industries, these structures combine durability, ease of installation, and adaptability to different environments. Unlike conventional buildings that require lengthy construction timelines and substantial financial investments, frame warehouse tents offer a cost-effective and efficient way to expand storage capacity, respond to urgent inventory demands, or establish temporary operational bases.

At the heart of a frame warehouse tent lies its structural design, which determines its stability, load-bearing capacity, and overall performance. Unlike tension-style tents that rely on fabric tension for support, frame warehouse tents are built around a rigid frame structure. This frame is typically constructed from high-strength materials such as aluminum alloy or galvanized steel, chosen for their lightweight properties and resistance to corrosion, rust, and wear. Aluminum alloy frames are particularly popular due to their portability and ease of assembly, while galvanized steel frames offer enhanced durability and load-bearing capacity, making them suitable for heavier storage requirements or harsher weather conditions.

The frame structure consists of several key components, including vertical columns, horizontal beams, cross braces, and roof purlins. These components are connected using specialized fittings that ensure stability and allow for quick assembly without the need for complex tools or professional construction teams. The roof and side panels of the tent are made from high-quality, durable fabrics such as PVC-coated polyester or polyethylene. These fabrics are engineered to be waterproof, UV-resistant, and tear-proof, providing reliable protection for stored goods against rain, sunlight, dust, and other environmental factors. Some advanced fabric materials also offer additional features such as flame retardancy and thermal insulation, expanding the tent’s usability in extreme temperature conditions or areas with strict safety regulations.

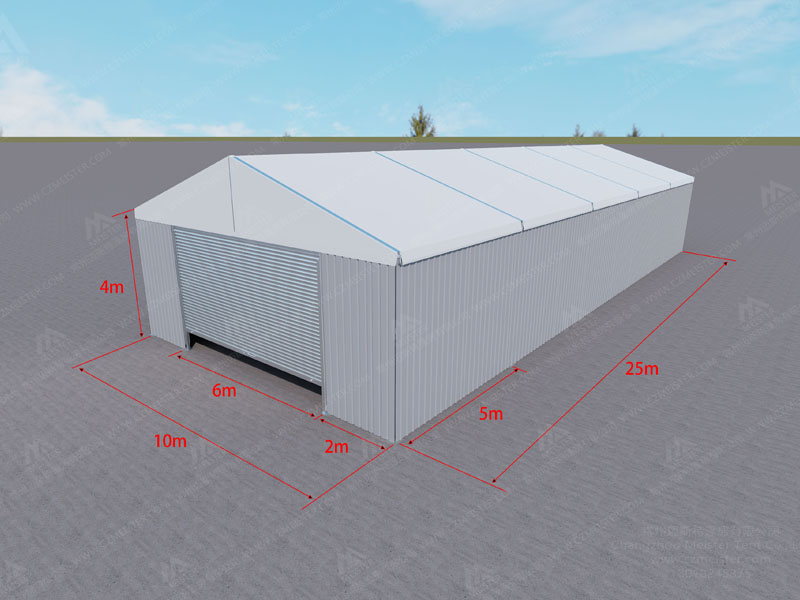

One of the most notable characteristics of frame warehouse tents is their modular design. Most models are available in a range of standard sizes, with widths typically ranging from 5 meters to 30 meters or more, and lengths that can be extended in increments (often 3 meters or 5 meters) to meet specific storage needs. This modularity allows users to customize the tent’s size according to the volume of goods to be stored, maximizing space utilization and avoiding unnecessary waste. Moreover, multiple frame warehouse tents can be connected together side by side or end to end to create larger, contiguous storage spaces, further enhancing their flexibility.

The applications of frame warehouse tents are diverse and span across numerous industries, reflecting their adaptability to different storage requirements and operational scenarios. In the logistics and transportation sector, these tents are widely used as temporary storage facilities for goods at ports, terminals, and distribution centers. During peak seasons such as holidays or promotional events, logistics companies often experience a surge in inventory, and frame warehouse tents provide a quick and cost-effective way to expand storage capacity without the need for permanent construction. They can also be used as temporary loading and unloading areas, protecting goods from weather damage during the handling process.

In the construction industry, frame warehouse tents serve as essential on-site storage solutions for building materials, tools, and equipment. Construction sites are often dynamic environments with changing storage needs, and these tents can be easily installed and relocated as the project progresses. They protect construction materials such as cement, steel, and wood from moisture and dust, ensuring their quality and usability. Additionally, frame warehouse tents can be converted into temporary workshops or offices for on-site personnel, providing a comfortable and protected space for planning and coordination.

Agriculture is another sector that benefits greatly from the use of frame warehouse tents. Farmers and agricultural businesses use these tents to store crops, fertilizers, pesticides, and farming equipment. During harvest seasons, when large quantities of crops need to be stored temporarily before processing or transportation, frame warehouse tents offer a convenient solution. They can also be used as greenhouses or temporary shelters for livestock, providing protection against extreme weather conditions such as heavy rain, strong winds, or extreme temperatures. The UV-resistant fabric of the tents ensures that crops receive adequate sunlight while being shielded from harmful UV rays, promoting healthy growth.

The manufacturing industry also relies on frame warehouse tents for various purposes, including raw material storage, finished product warehousing, and temporary production facilities. Manufacturing plants often face fluctuations in production volume, and these tents allow them to adjust their storage capacity quickly. In cases of equipment maintenance or factory expansion, frame warehouse tents can be used as temporary production areas to minimize downtime and ensure continuous operations. They can also be used to store bulky or oversized equipment that cannot be accommodated in conventional warehouses.

Beyond industrial and agricultural applications, frame warehouse tents are also used in disaster relief efforts, outdoor events, and military operations. In the aftermath of natural disasters such as earthquakes, floods, and hurricanes, these tents are quickly deployed as temporary storage facilities for relief supplies, food, and medicine. Their ease of installation and portability make them ideal for emergency situations where time is of the essence. For outdoor events such as music festivals, sports competitions, and trade shows, frame warehouse tents are used as storage areas for event equipment, merchandise, and catering supplies. In military operations, they serve as temporary storage facilities for weapons, ammunition, and other military equipment, as well as temporary barracks for soldiers.

The popularity of frame warehouse tents can be attributed to their numerous core advantages over traditional storage solutions. One of the most significant advantages is their cost-effectiveness. Constructing a traditional brick-and-mortar warehouse requires a large upfront investment in land, materials, labor, and permits. In contrast, frame warehouse tents are significantly cheaper to purchase or rent, and their installation costs are minimal due to the simplicity of the assembly process. This makes them an ideal choice for small and medium-sized businesses with limited budgets, as well as for organizations that require temporary storage solutions and do not want to commit to long-term financial investments.

Another key advantage is their quick installation and disassembly. Traditional warehouses can take months or even years to construct, while a frame warehouse tent can be installed in a matter of days or even hours, depending on its size and the number of personnel involved. This rapid deployment is particularly beneficial in emergency situations, peak seasons, or temporary projects where time is critical. Additionally, frame warehouse tents can be easily disassembled and relocated to other sites, making them a flexible and reusable storage solution. This reusability further enhances their cost-effectiveness, as they can be used for multiple projects or in different locations over time.

Flexibility and adaptability are also major strengths of frame warehouse tents. Their modular design allows for easy customization of size and configuration, enabling users to meet specific storage needs. They can be installed on a variety of surfaces, including concrete, asphalt, grass, and soil, without the need for complex foundation work. This makes them suitable for use in remote or underdeveloped areas where traditional construction is not feasible. Furthermore, frame warehouse tents can be equipped with a range of optional accessories to enhance their functionality, such as roller shutters, sliding doors, windows, ventilation systems, lighting, and heating or cooling systems. These accessories allow users to create a comfortable and efficient storage environment tailored to their specific requirements.

Durability and reliability are also important advantages of frame warehouse tents. The high-strength frame materials and durable fabric panels ensure that the tents can withstand harsh weather conditions such as strong winds, heavy rain, snow, and extreme temperatures. Most frame warehouse tents are designed to meet international wind load and snow load standards, ensuring their stability and safety in adverse weather. The waterproof and UV-resistant fabric protects stored goods from damage, ensuring their quality and integrity. With proper maintenance, frame warehouse tents can have a service life of 5 to 10 years or more, making them a long-lasting storage solution despite their temporary nature.

In addition to these practical advantages, frame warehouse tents also offer environmental benefits. Unlike traditional construction, which generates a significant amount of waste and consumes large quantities of non-renewable resources, the production and installation of frame warehouse tents have a much smaller environmental footprint. The frame materials are often recyclable, and the fabric panels can be reused multiple times. Furthermore, since frame warehouse tents do not require permanent foundations, they do not cause damage to the land, making them an eco-friendly storage solution for temporary or semi-permanent use.

While frame warehouse tents offer numerous advantages, there are also several important considerations that users should keep in mind to ensure their effective and safe use. First and foremost, it is essential to choose the right size and type of tent for the intended application. Users should assess their storage needs, including the volume and type of goods to be stored, the available space at the installation site, and the local weather conditions. For example, if storing heavy or bulky items, a tent with a galvanized steel frame and a high load-bearing capacity should be chosen. If the tent will be used in an area with strong winds or heavy snow, it is important to select a model that is designed to withstand these conditions.

Proper installation is another critical factor. While frame warehouse tents are designed for easy assembly, it is important to follow the manufacturer’s installation instructions carefully to ensure the structure’s stability and safety. In some cases, it may be necessary to hire professional installation teams, especially for larger tents or in areas with complex terrain or harsh weather conditions. Additionally, users should ensure that the installation site is level, dry, and free from obstacles such as rocks, trees, and power lines.

Maintenance is also essential to prolong the service life of frame warehouse tents. Regular inspections should be conducted to check for damage to the frame, fabric, and fittings. Any damaged components should be repaired or replaced promptly to prevent further damage. The fabric panels should be cleaned regularly to remove dust, dirt, and debris, and should be treated with waterproofing agents periodically to maintain their water resistance. The frame should be checked for rust or corrosion, especially if used in humid or coastal areas, and should be painted or treated with anti-corrosion agents as needed.

Safety considerations should also not be overlooked. Users should ensure that the tent is equipped with appropriate safety features such as fire extinguishers, emergency exits, and lighting systems. It is also important to comply with local safety regulations and building codes, especially if the tent will be used for commercial or industrial purposes. Additionally, users should avoid overloading the tent with goods beyond its load-bearing capacity, as this can compromise the structure’s stability and safety.

Looking to the future, the demand for frame warehouse tents is expected to continue growing as businesses and organizations increasingly recognize their flexibility, cost-effectiveness, and adaptability. Advances in materials technology are likely to further improve the performance of these tents, with the development of lighter, stronger, and more durable frame materials and fabric panels. Additionally, the integration of smart technologies such as temperature and humidity sensors, remote monitoring systems, and automated ventilation systems is expected to enhance the functionality and efficiency of frame warehouse tents, making them even more suitable for a wide range of applications.

In conclusion, frame warehouse tents have established themselves as a versatile and reliable storage solution for a wide range of industries and applications. Their unique combination of cost-effectiveness, quick installation, flexibility, durability, and environmental friendliness makes them an attractive alternative to traditional warehouses. Whether used for temporary storage during peak seasons, on-site storage at construction sites, crop storage in agriculture, or emergency relief efforts, frame warehouse tents offer a practical and efficient way to meet storage needs. By carefully considering the intended application, choosing the right size and type of tent, ensuring proper installation and maintenance, and adhering to safety regulations, users can maximize the benefits of frame warehouse tents and enjoy a long-lasting, reliable storage solution. As technology continues to advance, frame warehouse tents are poised to become even more indispensable in the modern world of storage and logistics.